EVOLUTION- ESPC

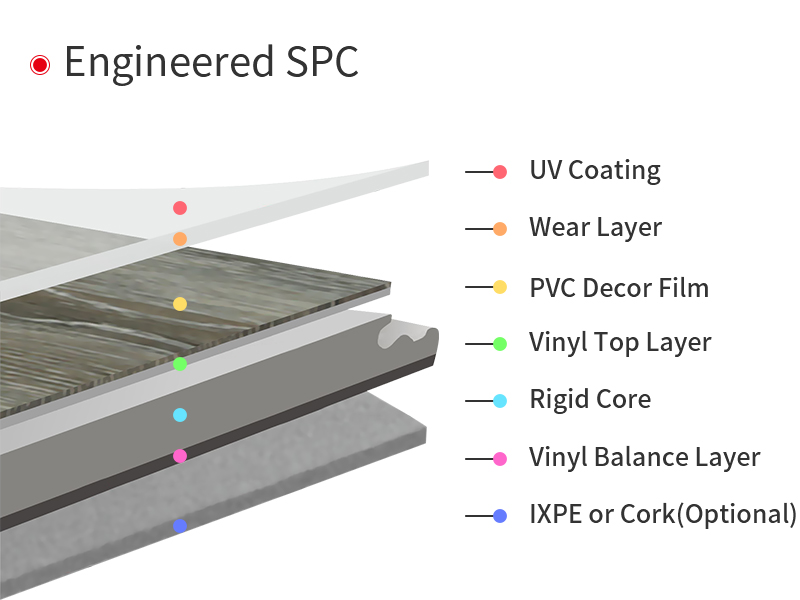

ESPC flooring combines advantages of both SPC and LVT, it remains the excellent dimensional stability, being water-proof,rigid of SPC ,but also provides softness of LVT.With IXPE cushioned backing. ESPC provides a quieter, warmer vinyl flooring.

Regular dimension

Dimension: 178x1220mm, 182x1220mm, 152x1220mm, 229x1522mm, 229x1830mm, 305x610mm

Thickness: 3.5mm, 4.0mm, 4.5mm, 5.0mm, 6.0mm

Wearlayer: 0.15mm, 0.2mm, 0.3mm, 0.5mm, 0.7mm

For more dimension, pls contact with the supplier.

|

ESPC

|

||

|

Thickness

|

|

4.5- 7.0mm

|

|

Density

|

|

1.88~1.94g/cm³

|

|

Wearlayer

|

|

0.3/0.5/0.7mm

|

|

Dimensional stability

|

ISO 23999:2008

|

X Direction: 0.03%

Y Direction: 0.02% |

|

Curling

|

ISO 23999:2008

|

≤0.5mm

|

|

Residual indentation

|

ISO 24343-1:2007

|

~0.04mm

|

|

Light stability

|

ISO 105- B02:Method 3

|

≥6

|

|

Castor chair

|

EN 425

|

Typ W

|

|

Classification

|

EN ISO 10582

|

23, 31/33, 42/34, 43

|

|

Reaction to fire

|

EN 13501-1

|

Bfl-S1

|

|

Slip resistance

|

DIN 51130 EN 13893

|

R10 DS

|

|

Wear resistance

|

EN 660-2

|

Group T

|

|

Thermal resistance

|

EN 12667:2001

|

0.042m²K/W

|

|

Determination of resistance to stains chemical rsistance

|

ISO 26987:2008

|

Resistant

|

|

Squareness

|

ISO 24342:2007

|

Deviation range:

X Direction: 0.00mm~ +0.05mm Y Direction: 0.00mm~ +0.05mm |

|

Straightness

|

ISO 24342:2007

|

Deviation range:

X Direction: 0.00mm~ +0.03mm Y Direction: 0.00mm~ +0.05mm |

|

Peel resistance

|

ISO 24345:2006

|

X Direction: 65N/50mm

Y Direction: 65N/50mm |

|

Burning cigarette test

|

EN 1399:1997 Method B

|

Rating 3: Moderate change of gloss and moderate brown stain

|

|

Utilization

|

|

Recyclable

|