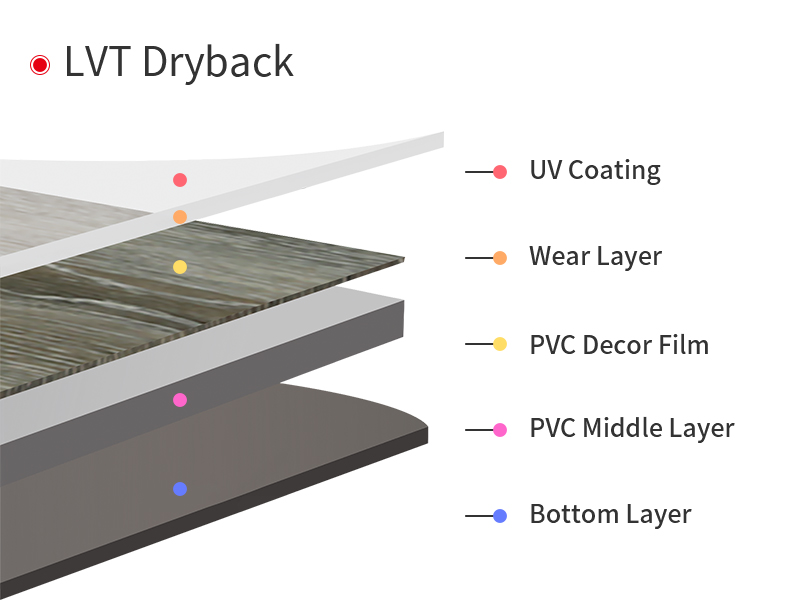

Generally Used -LVT

LVT Flooring is the earlier generation of PVC flooring, looks like real wood or real stone and has any design printed on it, and it also offers many practical benefits. It is produced in shapes of tiles or planks. With the Benefits of Waterproof, Great durability, Warmer ,Softer and flexible, limitless colours, easy and ideal for commercial and residential installations, LVT floors are always a popular product in the market.

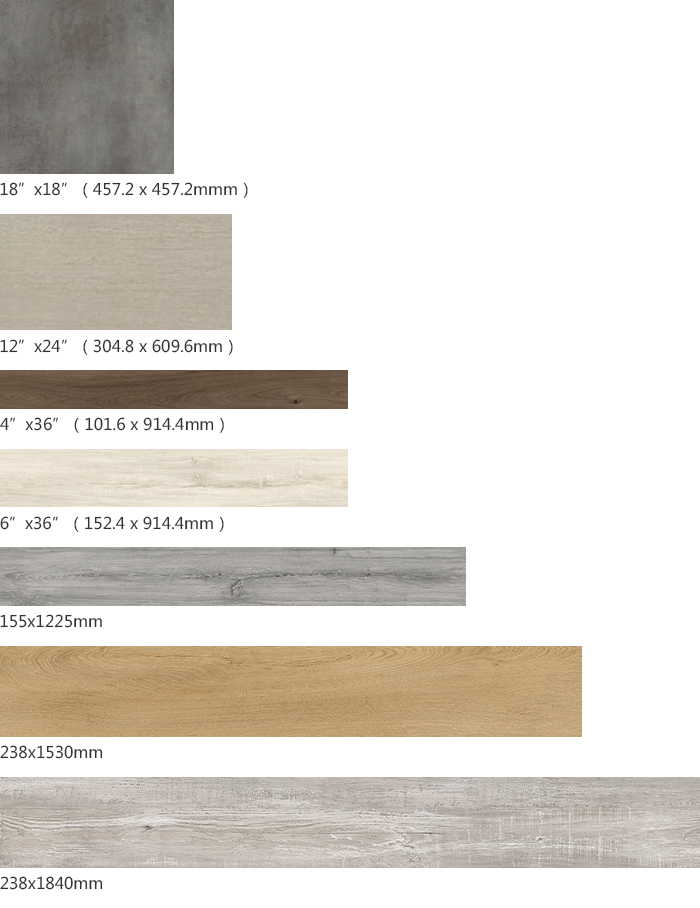

Regular dimension

Dimension: 4”x36”, 6”x36”, 12”x24”, 18”x18”, 155x1225mm, 238x1530mm, 238x1840mm

Thickness: 2.0mm, 2.5mm, 3.0mm, 4.0mm, 5.0mm

Wearlayer: 0.15mm, 0.2mm, 0.3mm, 0.5mm, 0.7mm

For more dimension, pls contact with the supplier.

|

LVT

|

||

|

Thickness

|

|

2.0-5.5mm

|

|

Density

|

|

1.8~2.02g/cm³

|

|

Wearlayer

|

|

0.3/0.5/0.7mm

|

|

Dimensional stability

|

ISO 23999:2008

|

X Direction: 0.12%

Y Direction: 0.10% |

|

Curling

|

ISO 23999:2008

|

≤0.2mm

|

|

Residual indentation

|

ISO 24343-1:2007

|

~0.04mm

|

|

Light stability

|

ISO 105- B02:Method 3

|

≥6

|

|

Castor chair

|

EN 425

|

Typ W

|

|

Classification

|

EN ISO 10582

|

23, 31/33, 42/34, 43

|

|

Reaction to fire

|

EN 13501-1

|

Bfl-S1

|

|

Slip resistance

|

DIN 51130 EN 13893

|

R10 DS

|

|

Wear resistance

|

EN 660-2

|

Group T

|

|

Thermal resistance

|

EN 12667:2001

|

0.074m²K/W

|

|

Determination of resistance to stains chemical rsistance

|

ISO 26987:2008

|

Resistant

|

|

Squareness

|

ISO 24342:2007

|

Deviation range:

X Direction: 0.00mm~ +0.05mm Y Direction: 0.00mm~ +0.05mm |

|

Straightness

|

ISO 24342:2007

|

Deviation range:

X Direction: 0.00mm~ +0.03mm Y Direction: 0.00mm~ +0.05mm |

|

Peel resistance

|

ISO 24345:2006

|

X Direction: 65N/50mm

Y Direction: 65N/50mm |

|

Burning cigarette test

|

EN 1399:1997 Method B

|

Rating 3: Moderate change of gloss and moderate brown stain

|

|

Utilization

|

|

Recyclable

|